Rock wool board is based on basalt and other natural ore as the main raw material, high temperature melting fiber, add the right amount of binder, curing processing and made, widely used in high temperature field, with good insulation, sound insulation effect. Construction and installation facilities, energy-saving effect is significant, with high cost performance.

Insulation and fireproof : Heat rock wool has low shots and slender and flexible fiber characteristics, in accordance with GB 10294, ASTM C177 and other standards for testing, thermal conductivity is low, which has excellent thermal insulation effect.

Excellent thermal stability : Rock wool products have good high temperature thermal stability, durability and resistance to high temperature shrink capacity; in the recommended temperature range and under normal working conditions, to maintain long-term security and stability and high efficiency (based on test methods GB / T17430, ASTM C411 / ASTM C447, ASTM C356).

Good corrosion resistance: Rock wool leachate pH value was neutral or weakly alkaline, carbon steel, aluminum (alloy), copper and other metal equipment or pipe corrosion. Low soluble chloride ion content, tested according to ASTM C795, no stress corrosion of austenitic stainless steel.

Moisture Resistance : Rock wool products exposed to 95 ° C for 96 hours at a temperature of 50o° Chave a volume moisture absorption of less than 0.2%. The mass moisture absorption of the rock wool products tested by ASTM C1104 / C 1104M is less than 1%. If this product is wetted, its insulation properties can be completely restored after drying.

Hydrophobic : hydrophobicity refers to the ability of a material to resist water penetration. Thistle hydrophobic rock wool has a water repellency of more than 98% (tested according to GB 10299).

Fireproof : Rock wool natural rock as raw material, sintering temperature up to 1050° C, the organic binder content is very low, according to GB5464-1999 and ISO 1182 to be tested, judged as non-flammable materials.

Sound absorption and noise reduction : rock wool is a kind of cost-effective sound-absorbing, noise-reducing and elastic vibration-absorbing material which has the porous connection of small air gap formed by slender fibers.

Nontoxic : Rock wool is asbestos-free, non-viable and has no microbial growth base. Rock wool has been recognized by the International Agency for Research on Cancer as non-carcinogenic.

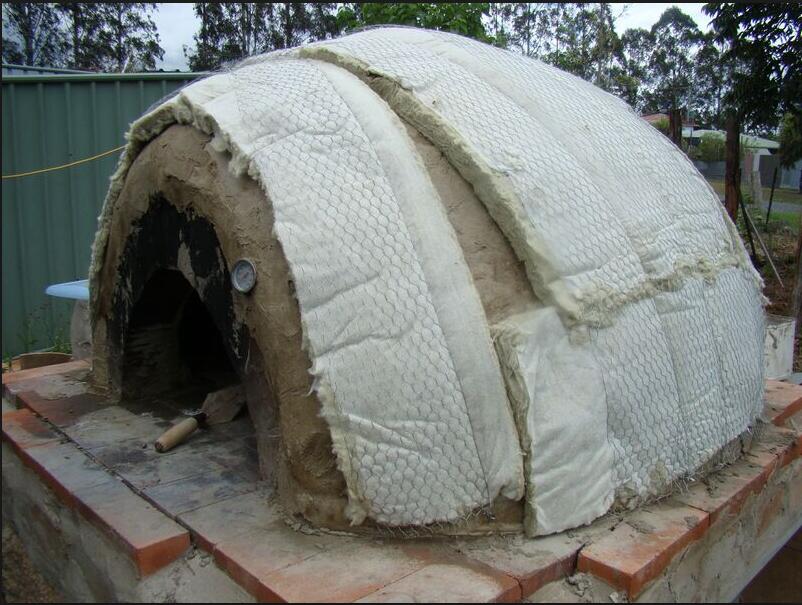

The industrial rock wool is mainly used for the insulation of the kiln. During the construction, the temperature and moisture resistance of the rock wool should be paid attention to. High quality Wood fired brick ovens 100% insulated with ROCK WOOL make your best choice with our wood fired Brick ovens!